Holo was my GHP project. This idea was selected from hundreds of other projects and was one of only 8 in the Engineering track.

Best project (engineering) from best class. Green lighting process - where many projects are submitted but only a few are selected. A few hundred projects were submitted. Design, engineering, and computer software projects. Only 5 projects were selected from the engineering track and mine was one. Each project had to incorporate someone from each area.

We designed Holo based on an old principle called Pepper Ghost where a piece of translucent material is placed at a 45 degree angle to a projector. Thereby allowing you to see through the material and simultaneously seeing the projection. This gives an illusion of a ghost, or in our case a hologram. We used this idea to create a rectangular pyramid with a LCD screen placed above it as a “projector” so that any image that we placed on the screen and turned into a four way split image would render as a solid object inside of the rectangular pyramid.

I have been flying drones since I was 9 years old and began customizing drones to my own specifications by age 12. I started building drones because I was looking for a way to elevate my engineering skills from fabrication-focused to higher level electrical engineering and complex system development.

I have broken a personal barrier by increasing my knowledge base through my access to and understanding of aerial vehicles and radio communications.

The most recent drone I created was a 5-inch analog FPV. To construct it I salvaged material from previous drones that I built including a flight controller, radio receiver, video transmitter, analog camera and brushless motor. By doing this I minimized the outsourcing of parts and only had to acquire a few items like the carbon fiber frame and the 60amp ESC. This custom platform had enough thrust to carry my iPhone Pro to record gyrostabilized 4k 24fps footage (see AV page).

I find specific techniques or technical challenges that I try to learn about through a project. In this case it was motorized vehicles with enough power to move an actual person. Higher power req, higher strength req for hub motor mounts, and heat - had to factor in thermal electrical heat due to the high amount of current being discharged. To construct this I used PLA to produce filament in the battery compartment, 18650 battery cells that are rechargeable and also are a stable energy platform, meaning excessive heat won’t cause too much of any issue. I used an older bike frame that I then retrofitted the components to.

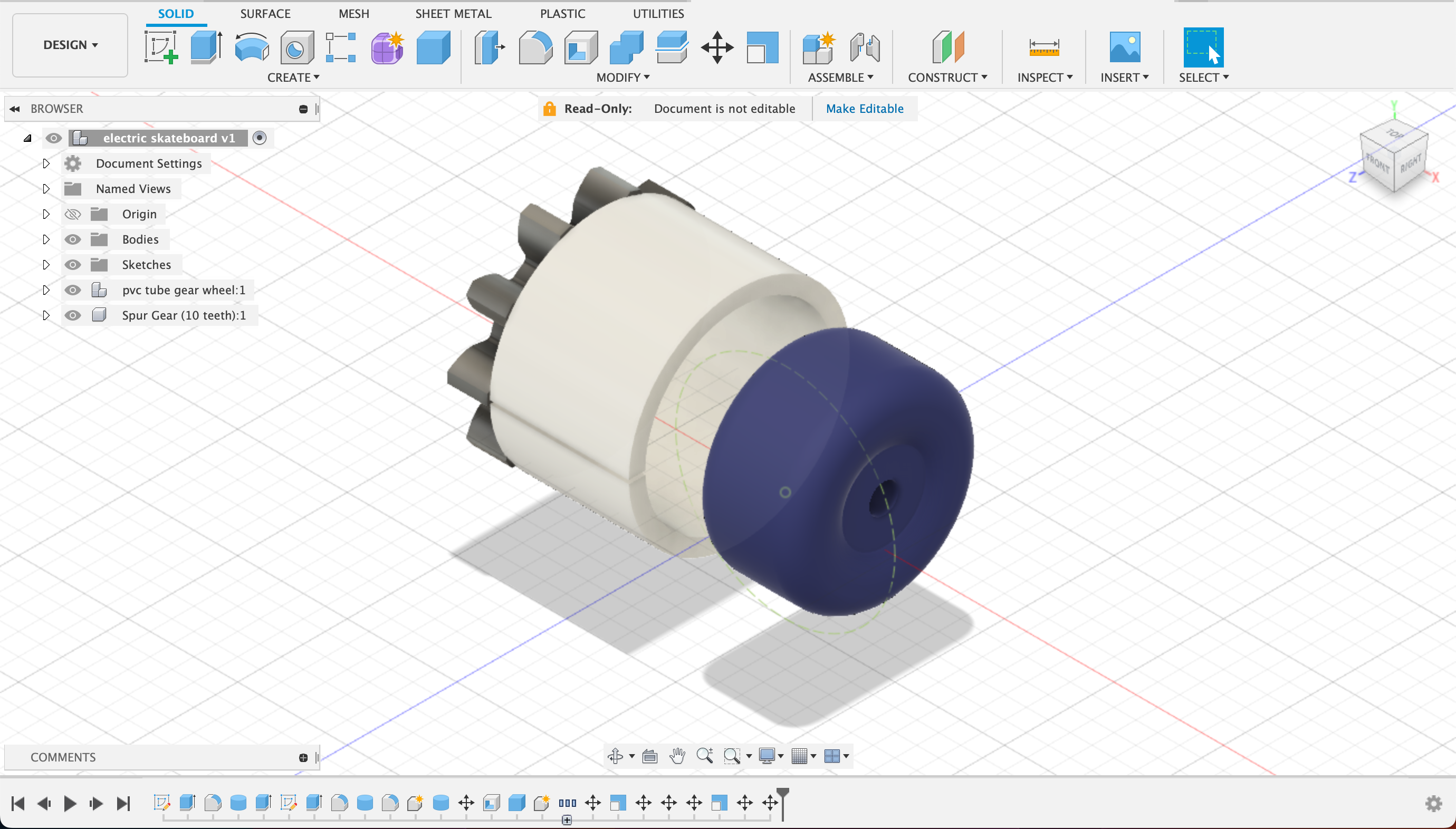

I've worked in Fusion 360 and Blender providing several years experience in CAD where I've done simulations, material application and 3D prototyping. I have used these skills to create prototypes for many innovations and original inventions. Created a containment unit to house 18650 battery cells that held 10-12 individual batteries. This was used for a bicycle format that I fabricated from bicycle components (moped form). Created a method for motorizing a skateboard. Design for a motorized skateboard - configuration of a PVC and a 3D printed gear. Modern yarn bowl. Robotic hand.

Electrical engineering is the way in which I can truly innovate in technology as a whole. Through EE accompanied by mechanical design I can produce new creations and systems that can benefit the world, particularly underserved and rural/remote areas. Focusing on sustainable technologies I intend to drastically increase the accessibility to electrical power through solar, electrochemical or other means. I am currently going through older technologies and patents because I am firm believer that the technologies of the future lie within the discoveries of the past.

I learned programming integration and the use of microcontrollers, like the one used in the large amp I designed. I learned how to design PCBs and integrate the base component of microcontrollers which are microprocessors. Next steps include innovate PCV design.

At the age of 12 my journey as a "Maker" began. Inspired by Star Wars and adventure stories, I crafted faux weapons made from wood and household items like foil or electrical tape. In addition to this broad sword, I also made a really cool light saber. I have a video attached showing off my Jedi skills.

I designed pneumatic systems to launch rudimentary projectiles, the guitar was made out of ⅛ in plywood and reclaimed pallet wood. It used 11 to 14 size guitar strings and six eye-bolts connected to steel brackets to tune said strings.